Empowering Your Competitive Position with

-

Quick Access

MachineLink+ provides built-in standard access models and related analysis algorithms, making you rapidly access various types of equipment. Support the collection and analysis of common data such as working hours, energy consumption, mileage, etc.

-

Wide Service Coverage

MachineLink+ has expanded its services to more than 100 countries and regions around the world through our excellent partners, and we have stable and excellent network links to cope with the network transmission challenges in different countries and regions.

-

Highly Expandable

MachineLink+ supports access model customization, enabling custom expansion of various device-specific fields.

Our service-less architecture allows customization of services and page components according to individual needs.

Machine + IoT = Limitless Possibility

Accumulating years of industry experience, we provide manufacturers with scenario-based equipment management services, allowing quick verification of IoT values at reduced costs.

-

Asset Monitoring

-

Geofence

-

Collision Alarm

-

Driving Track Logging

-

Fuel Theft Monitoring

-

Health Diagnostics

-

Machine Lock

-

Maintenance Management

-

Energy Consumption Reporting

-

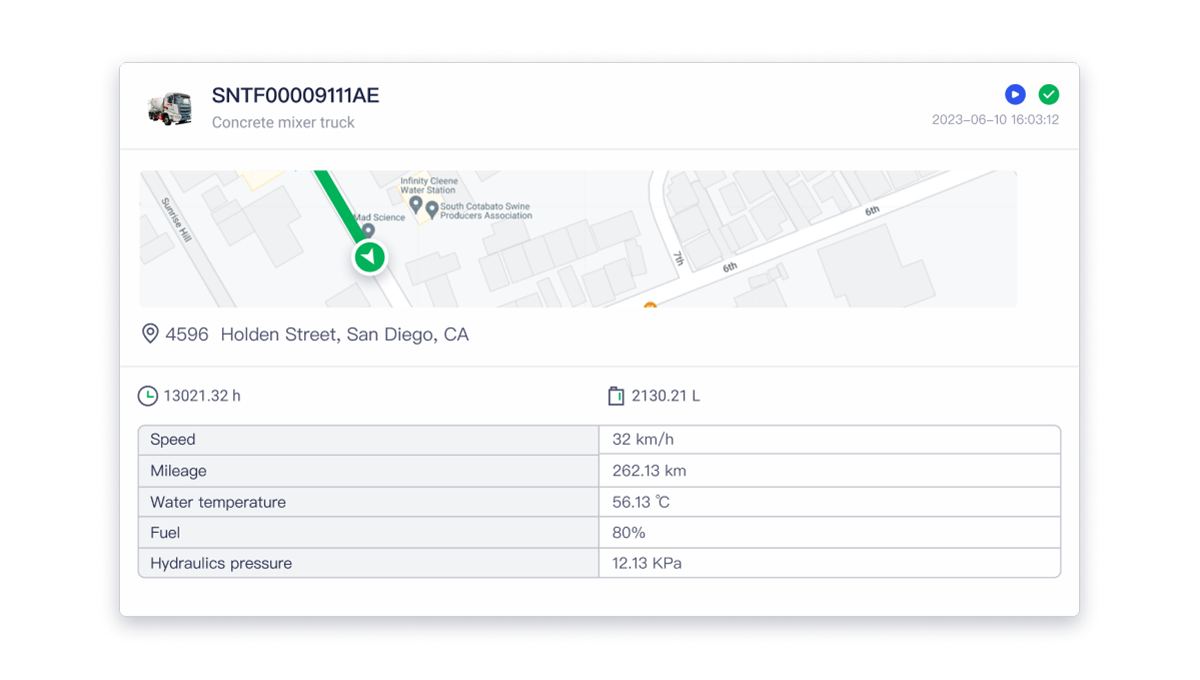

Asset Monitoring

Equipment distribution overview, working status, core working indicators.

Presents real-time data including location, fuel consumption, mileage, and temperature.

-

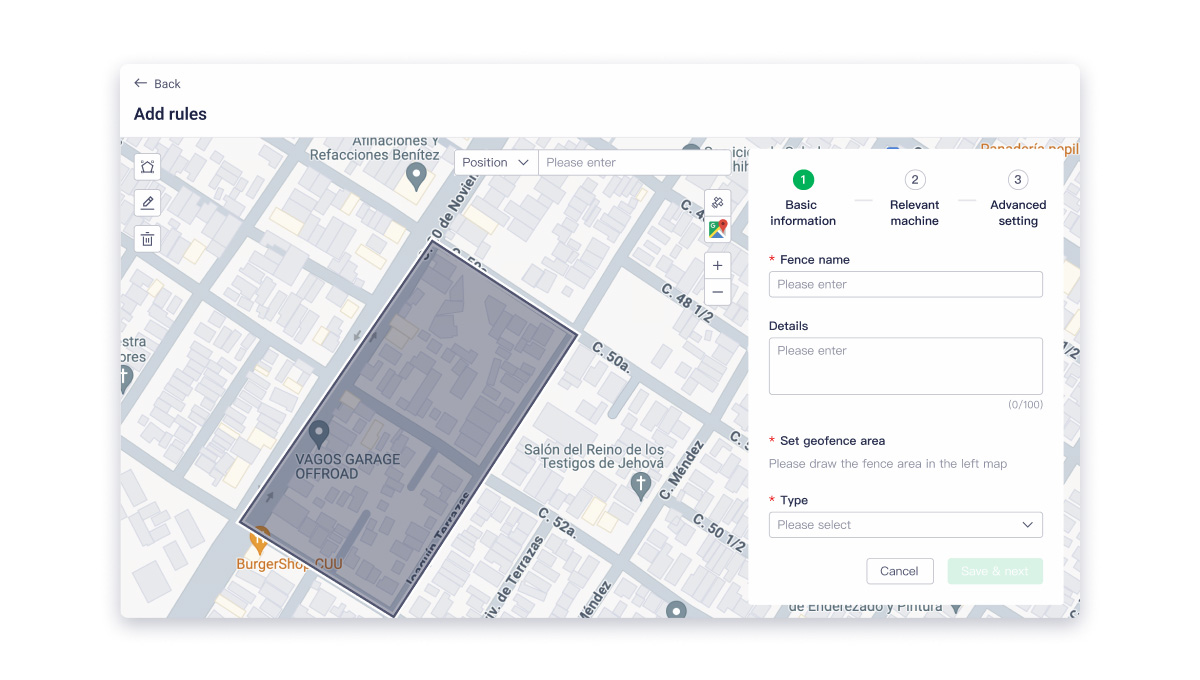

Geofence

Configure custom construction zones and receive alarm notifications when equipment enters or leaves these zones. Implement geofence controls in both contracted and restricted areas to immediately expose any unauthorized activities, thereby making the management process more worry-free.

-

Collision Alarm

Equipment distribution overview, working status, core working indicators Presents real-time data including location, fuel consumption, mileage, and temperature.

-

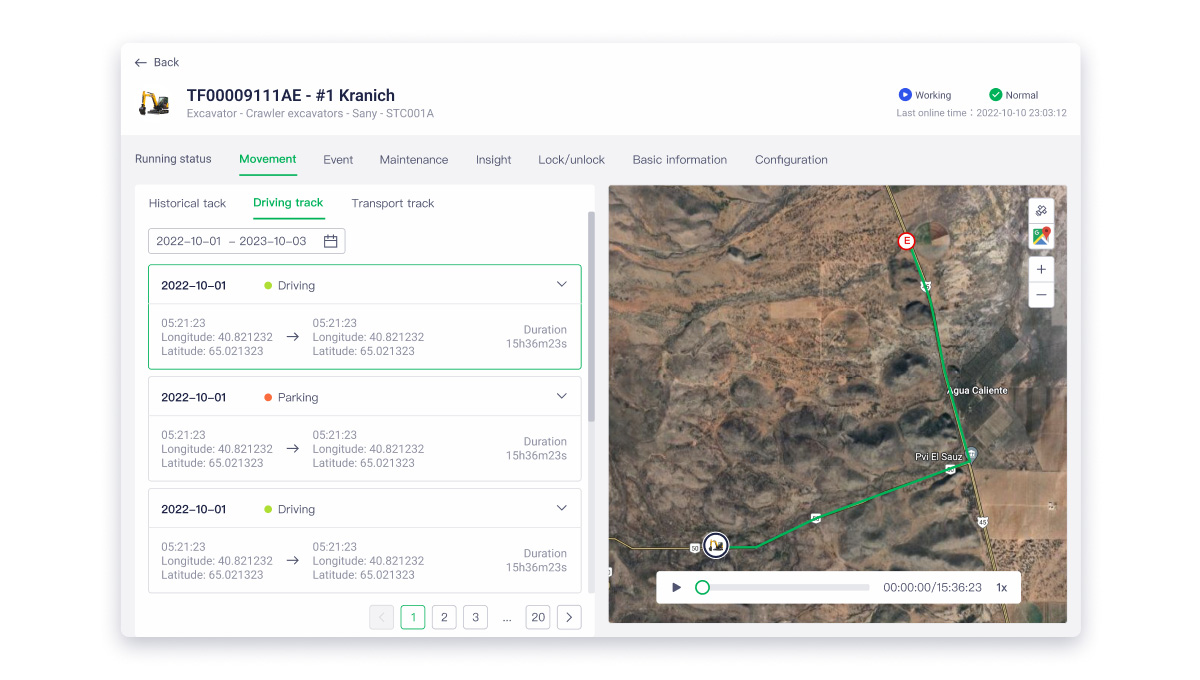

Driving Track Logging

Integrated with the outlined drivable area for the equipment and its abnormal displacement tracking, notifications are instantly sent to the equipment administrator if the equipment leaves the specified area or if displacement occurs when the equipment is off. This ensures real-time tracking of the equipment's path and movements.

-

Fuel Theft Monitoring

Equipment distribution overview, working status, core working indicators Presents real-time data including location, fuel consumption, mileage, and temperature.

-

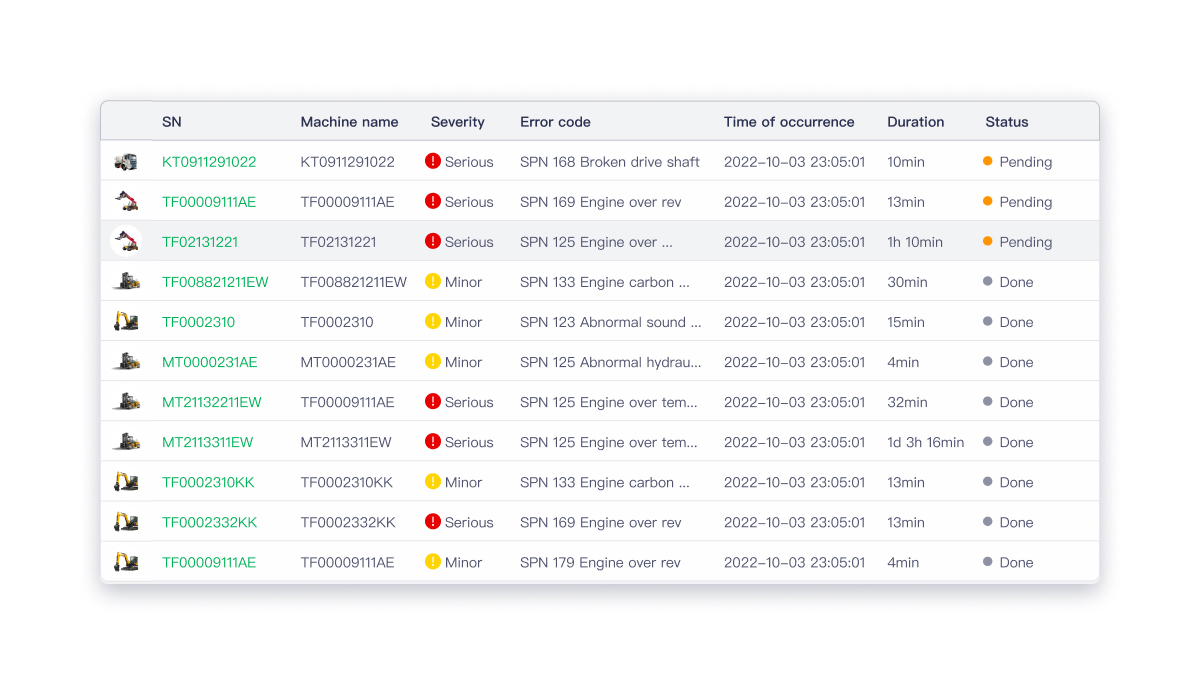

Health Diagnostics

We collect and analyze equipment failure codes, automatically identify issue severity and priority, and push fault alarm notifications. By proactively identifying and maintaining equipment before issues escalate or costs rise, we help decrease downtime.

-

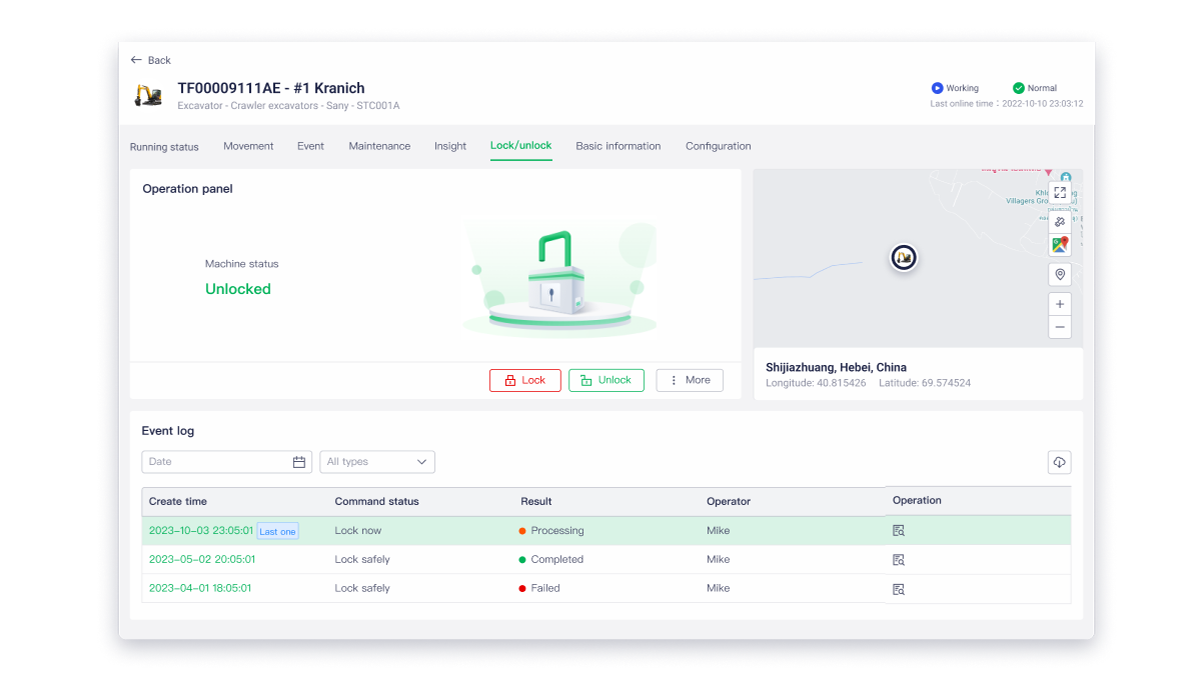

Machine Lock

Utilizing remote machine lock feature, limits equipment movement and operations. In the case of customers past due on payments, remotely lock the equipment to restrict its normal operation, safeguarding equipment assets and promoting payment collection.

-

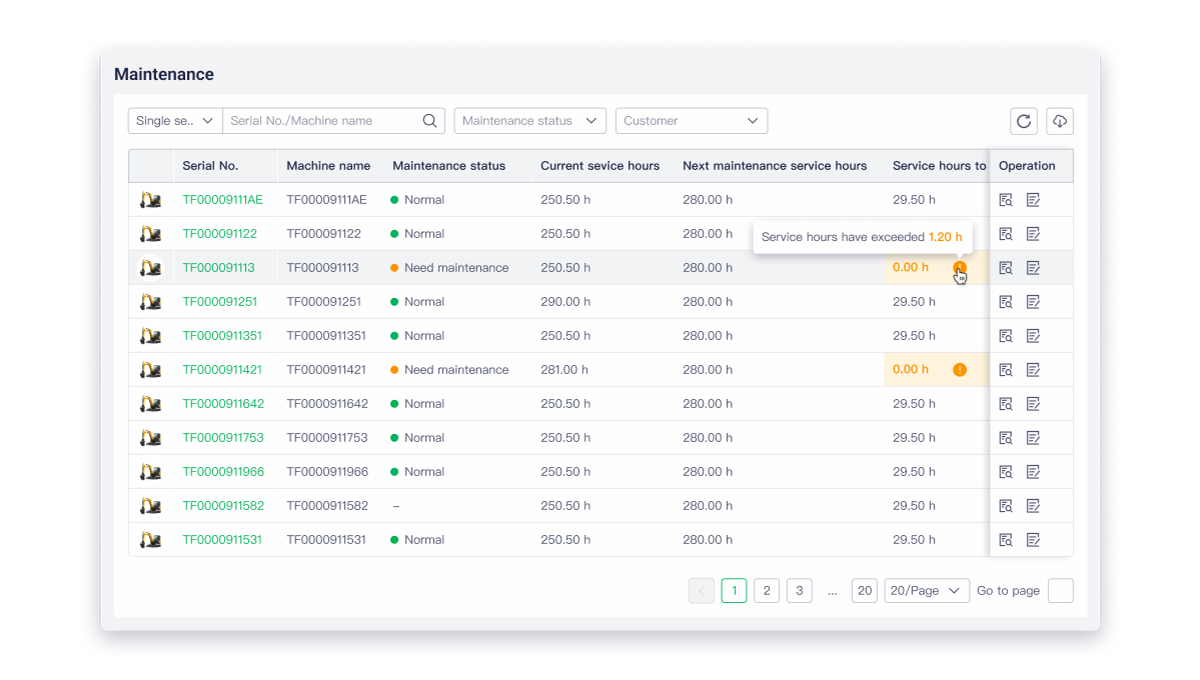

Maintenance Management

Customize maintenance rules based on service time and distance, estimating when upkeep is needed. Notifications are sent when the equipment is due or is about to undergo maintenance, generating comprehensive service records. This ensures a complete asset maintenance history for your equipment

-

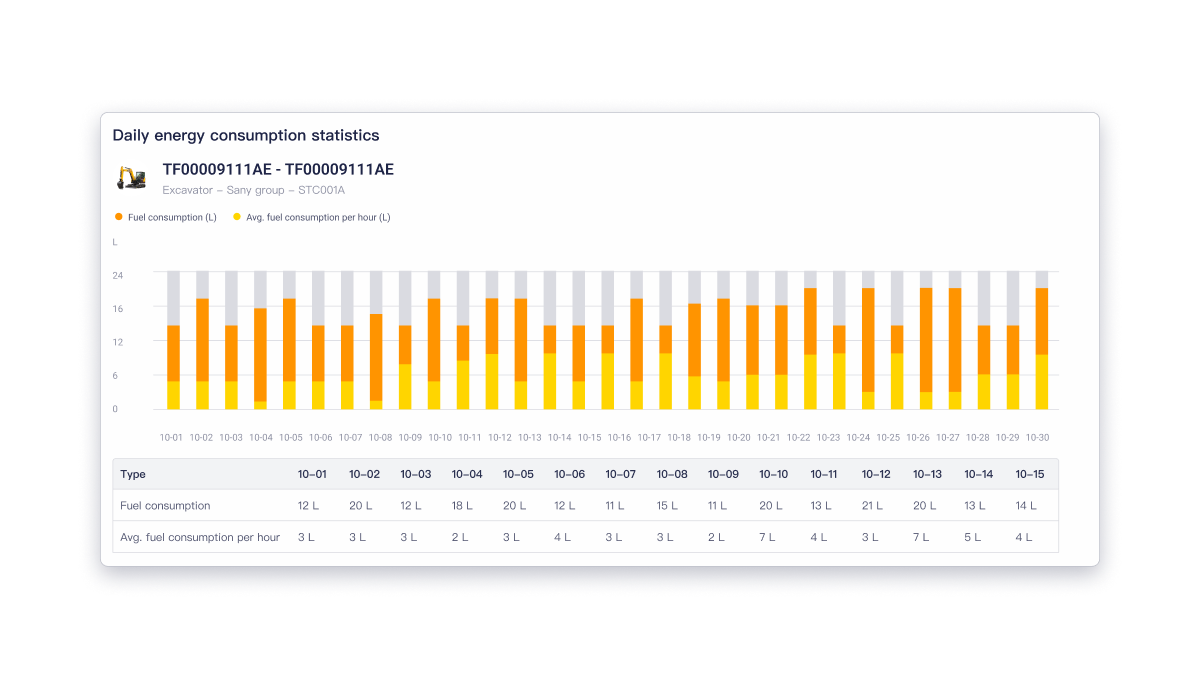

Energy Consumption Reporting

Equipment distribution overview, working status, core working indicators Presents real-time data including location, fuel consumption, mileage, and temperature.

See Real-World Possibilities

-

OEM Aftermarket Management

OEM Aftermarket ManagementWhen your products are sold, they can still be linked to end customers, increasing after-market revenue and reducing after-sales service costs.

-

Construction Unit Equipment Management

Construction Unit Equipment ManagementYou can comprehensively monitor equipment construction, analyze equipment hours, fuel consumption, alarms and other information to improve construction safety and utilization.

-

Rental Company Equipment Management

Rental Company Equipment ManagementYou can monitor equipment usage post-rental, ensure timely maintenance to reduce costs and use machine locks to facilitate payment collection.

T-AMS Supports MachineLink+, Enabling Rapid and Cost-Efficient Validation of the Value of IoT Application Scenarios

Working with Some of the Best

How Can We Help

-

Talk to Our Expert

Connect with our global experts for customized solutions and support.

-

Request a Custom Solution

Create tailor-made solutions that align perfectly with your business.

-

Access to the Resource Library

Explore our resources to fuel your digital transformation and master the nuances of Industry 4.0.